Comparison of Belt, Chain and Gear drive

Contents

Difference Between Belt Drive, Chain Drive and Gear Drive with Comparison Chart

Summary:

The major difference between Belt drive and Chain drive is that the Belt drive is one friction drive, and Chain drive is one engagement drive. Both a chain drive and a belt drive allow locomotion and transfer the power within a particular piece of machinery. Chain drives and Belt drives used in bicycles, motorcycles, and automobiles.

Comparison Chart

| Belt drive | Chain drive | Gear drive |

|---|---|---|

| Main element Pulleys, belt | Main element Sprockets, chain | Main element Gears |

| Slip may occur | No-slip | No-slip |

| Suitability For the large center distance |

Suitability For the moderate center distance |

Suitability For the short center distance |

| Large Space requires | Moderate Space requires | Less Space requires |

| Simplest Design, manufacturing, complexity |

Simplest Design, manufacturing, complexity |

Complicated Design, manufacturing, complexity |

| Failure of the belt does not cause the further damage of machine |

Failure of a chain may not seriously damage the machine. |

Failure of gear may cause serious break down in the machine. |

| Less Life | Moderate Life | Long Life |

| Lubrication Not required | Lubrication required | Requires proper lubrication |

| Less Installation cost | Moderate Installation cost | More Installation cost |

| Used For low-velocity ratio | Used For moderate velocity ratio |

Used For high velocity ratio |

Chain Drive

Slipping occurs in belt and rope drives. In order to avoid these slipping phenomenon chain drives are used. A

chain drive consists of three elements

- Driving sprocket

- Driven sprocket

- An endless chain which is wrapped around two sprockets

Advantages of Chain Drive

- It provides a positive transmission and no chances of slip are there.

- It gives a constant velocity ratio

Applications of Chain Drive

- It is used in bicycle, motorcycles, agricultural machinery and textile machinery, material handling equipment

etc.

Types of Chain

- Hoisting and Hauling chains

- Conveyor chains

- Power transmission chains

Gear Drive

- A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to

transmit torque and power. - In order to transmit a definite power from one shaft to another shaft to the projection on one disc and recesses

on another disc can be made which can mesh with each other. - In the early days, friction discs as shown in the figure were used for transmitting the power from one shaft to another shaft. In such a case, the power transmission capacity depends on the friction between surfaces of two discs. Therefore, this method is not suitable for transmitting higher power as a slip occurs between the discs.

Advantages of Gear drive

- It is a positive drive (no slip) i.e. it transmits exact velocity ratio from one shaft to another shaft.

- It can transmit very large power.

- High transmission efficiency.

- It requires less space.

- This drive is more reliable.

Disadvantages of Gear drive

- Manufacturing cost is high.

- Maintenance cost is also high due to lubrication requirements.

- The error in cutting teeth may cause vibrations and noise during operation.It requires precise alignment of shafts.

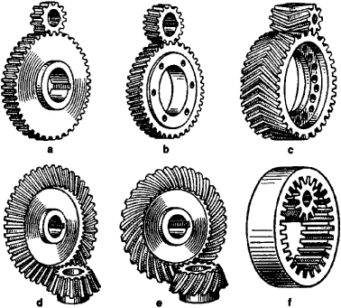

Types of gears

- Spur gear

- Helical gear

- Rack and Pinion gear

- Bevel gear

- Worm and worm wheel

- Spiral gear

More Differences

- Difference Between Vapour Compression and Vapour Absorption System

- Difference Between Individual Drive and Group Drive